武田机电

DAESUNG振动设备,DAESUNG干燥冷却系统,DAESUNG磨机及混合机,DAESUNG渣粒化系统,DAESUNG挤压机系统.

DAESUNG振动给料机,振动筛,振动输送机

DEASUNG广泛应用于食品加工,制药及化工及行业.

Twist Screen

The twist screen of Daesung Machinery creat 3-dimensional vibration direction quantity by

vertical vibrator, so that handling material moves during vibration movement from center to outside.

At this time, smaller particles than mesh opening size or wet material drops below mesh,and larger particles than opening size remaining on the mesh or sludge material drops from

outlet during circular motion to outer side

Ultra Sonic Seving

Currently sieving system users want the machine that screen blinding and clogging dont

occur on the sieve mesh with highest seperating speed. Former sieving technlolgy have developed by vibration / unduration machanics and these movment machanics have known that control the efficiency of removing foreign materiats, putting in particle, seperation materials.

In addition to the conventional method, Daesung Ultrasonic supported sieving technology evenly transmits an oscillation motion, in the micron range, onto the screen surface

Vibrating Screening

● This model is easy to adjust of amplitute and simple to maintenance by using Daesung rotary vibrator of high efficience.

● This model is simple to replace with screen unit (wire mesh). Changing time for

1 deck required takes about5~10min (DESI 1200-30 series)

● Area of screen unit forms rectangle which is easiest for screening work so that

maximization of screening efficiency may be expected.

● Anti-clogging device is attached to suppress grain clogging phenomenon of mash

during screening so that effect of consistent screening may be guaranteed.

● Slope of net to ideally control flow speed of screening object is composed of 8° ~ 13° and 13° ~ 18°

Vibrating Feeder

● Simple structure and easy to maintenance.

● It is in order after long term use as good durablity.

● It is cover up type so that better sanitary and prevention of mixing foreign material.

● Easy to control of feeding capacity and excellent to match of processing design

● Easy to design of layout as standardization of machinery.

● It is possible to appliy the complex process of transport,cooling,drying and keep consistent.

● It is possible to effect transport of micro powder, big particle, hot material, handing material

Magneting Feeder

● DSMF series magneting feeder of electronic resonance type is a deviece to cause vibration by giving strong

electromagnetic force to drive part trough converting alternating single phase electricity into pulse current with controller,

to convert feeding quantity simply during operation with voltage conversion type.

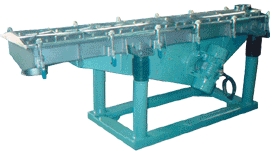

Vibrating Conveyor

● This reduces maintenance cost remarkably as compared with other equipment because it can generate large efficiency with small drive force by generating vibration through resonance between trough and counter weight.

● This enables complete airtight structure so as to prevent any powder from flying

in the air.

● This is enables to easy maintenance with simple structure and very small area of

rolling and wearing.

● This enables works such as drying, cooling, dehydration, selection, washing, etc.

so as to be used in various field.

● Daesung conveyor can generate vibration, which is resonance force from interaction trough and counter-weight, high efficiency and easy maintnance let the cost be

drereased. This can multiplex the number of input places and the number of discharge places using damper

Advantage Daesung stationary fluidzed bed drying system is a most efficient equipment for drying and cooling of crystals, granules powders. The benefit is as below. ● High conductivity ● Enable to handling large capacity compared with short retention time ● Easy to maintenance ● Uniformed dry and cooling efficiency. Daesung FBD Series enable to apply continuos type and batch type,and use hot wind,mixed gas,solvent vapours. It operations pilot test for making most suitable fluidize bed. Continuous Drying & Uniformed Dry Efficiency It can be applied to continuative process by continuous the raw material supply and quantitative discharge using vibration conveying. And it makes fluidized bed layers by supplying hot air and cold air from the low part of perforated plate. By forming proper fluidized layers, it is possible to keep uniform and high drying efficiency. Economic Equipment All necessary process steps can be combined for an optimum result. The final product is generated directly from pastes, In case of already existing general stationary fluidized bed dryer, transportation air should be supplied additionally besides drying air needed for dry, because it has to be designed to carry the products by hot air. Therefore more air should be supplied than actually needed air. Because of additional un-exchanged hot air due to above reason, exhausted air temperature rises high. The amount of exhausted air is pretty bigger, so the final applications such as dust collector and induced draft fan comes bigger more than needed. In vibrating mode, the products can be conveyed using the power of vibration. In this way, it is possible to supply only needed amount of drying air and minimize capacity of the final application more than 60%, which gains great efficiency.

Air Classifying Mill This pulverizer has a classifier in the grinding chamber so it can freely adjust the particle size. It is widely used for chemicals, powder coatings, foods, nonferrous metals, and others. It is easy to clean and is suitable for multi-product production Pin Mill Known as general-purpose mill, Pin Mill has a structure that many pins are built on the rotating disk and the fixed disk. It is widely used for not only crushing, but also fine-grinding. In addition, it is applicable to various types of materials so its application in powder processing is very wide. Hammer Mill & Atomizer Mill The mill has a number of hammers attached on the rotating rotor, and in its inner casing the mill is fitted with an irregularly shaped liner. Source materials are fed into the crushing chamber on a quantity basis by using a natural fall or a screw feeder. At the moment the materials are milled by striking first against the rotating hammers and then against the liner. If they are milled to the targeted size, then the mill discharges particles through the screen. If there are any larger-size particles that have failed to move through the screen, they go through the milling processes again. The system is very convenient to use as the particle size can be easily controlled by adjusting the rotational speed of the rotor, making a change in the number of hammers, and/or replacing the screen. According to whether a screw feeder is set up, the machine is divided into two types: hammer mill(with no screw feeder) and atomizer mill (with a screw feeder) Roller Mill Once source materials are fed into between two rotating rollers, they are milled into needed suitable-sized particles by the roller gap and the processing groove. When you need to get uniform-sized particles or minimize the generation of powder particles, the roller mill will provide you with the best solution. Fitz Mill Fitz Mill that is extensively used for milling millet seeds has simple structure. It is simple to operate and easy to change milling particles. The rotating rotor has many numbers of milling blade in the shape of knife. Unlike the hammer mill, shear force works more than shock power so it can mill a material into a particle suitable for the processing while suppressing the creation of minute powder. On the lower part of the milling blade, there is a screen of punched plate type so by changing the hole size of the screen and the rotating speed of the blade, the milling particle can be changed Mixer Mixing is one of the important procedures in ingredient process. However, people usually ignore or even never consider of it, so, in most cases, workers pay less attention to the mixer. If the ingredients were not well mixed, the important direction and quality control system would not receive the expected result. Advantages of the double-shaft paddle mixer are fast, uniform, and comparing with the ordinary mixer, it is less area and electric consumption. V-Mixer Turdulent Mixer Ribbon Mixer Gravity Mixer

Spiral Elevator

As a device to perform vertical transportation role and drying or cooling role simultaneouly, installation area can be minimized and staying time can be controlled by inverter, so that optimum drying or cooling efficiency can be controlled simply.